You can find two different kinds of fusible interfacing : woven and non-woven. What are the differences between the two? Is one better than the other?

Here is an article that, I hope, will enlighten you on the subject.

When you start sewing, interfacing is not the primary concern, and beginners tend to ignore it completely. But when advancing, you’ll quickly realize that this is a necessary supply to stabilize some areas of your sewing projects and get neat finishes.

I’m shouting out loud my love of interfacing: interfacing is glamorous! So today I’ll be talking about the two main types of fusible interfacing: woven and non-woven.

Difference between woven and non-woven interfacings

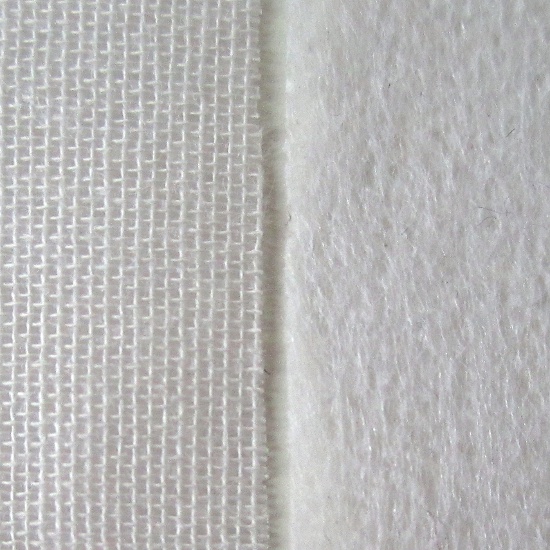

It’s rather obvious when you look at it :

- The woven kind is a cotton fabric with one side (the rough one) primed with fusible glue.

- The non-woven kind consists of agglutinated and compressed fibers and one side (the rough one) is primed with fusible glue.

As a result, the woven fusible interfacing looks and behaves like fabric and the non-woven looks and behaves like a sheet of paper.

Both types of fusible interfacing are available in various thicknesses and even in stretch varieties to interface jersey,…

Some Vilene references :

- Woven : G700 (medium), G710 (light), G785 (stretch).

- Non-woven : H200 (medium), H180 (light), H608 (stretch).

How to cut the interfacing

- The woven interfacing must be cut as fabric would : respecting the grainline.

- The non-woven interfacing can be cut “as it comes”, in any direction.

So the non-woven is easier to cut and as it can be cut in any direction, regardless of the grainline, nothing will go to waste.

Once fused to fabric

A fabric fused with a woven interfacing will continue to behave like fabric. It will keep a “natural” drape and hand.

A fabric fused with a non-woven interfacing will look stiffer. In my experience, if the non-woven was not perfectly applied, and sometimes even if it was applied properly, crinkles and creases will appear on the right side of the fabric.

Whether visually or by touch, the woven fusible interfacing always looks and feels better.

The price ?

The non-woven fusible interfacing is usually cheaper than the woven kind, especially if you buy “brands.” In France, I often buy woven “generic” (unbranded) fusible at 3 euros per meter : cheaper that any branded non-woven fusible.

You surely got that I am on the side of woven interfacing. I use it for almost all my sewing projects whether it be clothing, bags or accessories.

Great tips, I’m Spanish and I didn’t know the difference between them and how to translate into Spanish. I’ve learn all about sewing in English!

Hi Charo,

I’m glad you find it useful.

I’m French and learned a lot about sewing in English too 🙂

I’ll be on vacations in Spain really soon , I can’t wait !

I am using fabric interfacing for my raw silk outfits, however the interfacing is leaving bubbles in the fabric. When I do smaller pieces of fabric like half a meter or cut pieces in particular patterns it works well and sticks well. But if I do it for a piece of 6 mtr fabric or 5 mtr fabric continuously then it leaves bubbles in the middle and it looks really bad. can you help me with a solution please?

In Gratitude

Hello Cherry,

I’ve never interfaced that much length of fabric in one piece. The bubbles might be caused by some areas not being fused properly (but I guess that you take care to do it well).

Are you already using woven interfacing ? If not you might want to give it a try.

You should also wait until the area you’ve just interfaced is totally cooled down before handling/moving the fabric to interface the next area. If you move it while it’s still hot, the glue might not be perfectly set.

I am wanting to make a t-shirt quilt and would like to know which interfacing to use, woven fusible or non woven. There are various kinds when I went to fabric store. Please advise.. thank you!

Hi Bety,

Woven fusible interfacing is always the one I choose.

Vilene G700 or G710 for non stretchable fabrics or Vilene G785 for stretchable fabrics.

Would non-stretchable woven interfacing work for t-shirt fabric that will be made into a blanket/quilt? The finished product will not be stretching and the backing fabric will not be stretchable. Thanks!

Thank you for clearing this up for me.

Hi, which interfacing do you recommend for face mask, woven seems more breathable it has glue on one side so could act as some barrier,

non woven may be not be breathable, what’s your opinion

Conge

Hi Conge,

I wouldn’t recommend interfacing for a face mask, the glue could indeed impair breathability.

The AFNOR (which is an organization that provides guidelines in France for manufacturing among other things) has had several combinaison of fabrics used for face masks tested for eficacity and breathability, amidst the COVID-19 pandemic.

One of the combinaison of fabrics that is fairly protective, breathable and can be used easily by home sewists is 2 layers of cotton poplin.

You can check out this document, in French, to see the results of the tests : https://www.ifth.org/wp-content/uploads/2020/04/base-de-donnees-matieres-resultats-dga-maj-28042020.pdf

I’m making a pillow cover using a tight weave cotton fabric (about the weight of a good quality quilting fabric). What would you recommend to give it more body? Woven interfacing, iron on fleece interfacing, regular sew in lining?

Hi Hannah,

I would use a regular sew-in lining.

The pillow cover will be washed quite a lot so I think it’s the more durable option.

Woven and non-woven fusible interfacings may seem like small details in the sewing world, but they make a big difference in the outcome of your projects. Woven interfacing mimics the structure of fabric, with threads woven together, making it more flexible and ideal for garments where you want the fabric to retain a natural drape. Non-woven interfacing, on the other hand, has no grain and feels more like paper, offering consistent stability that’s perfect for projects like bags or collars that need a stiffer structure. So, is one better than the other? Not exactly—it depends on your project! Woven is best when you want a fabric-like finish, while non-woven shines for more structured needs. Don’t skip interfacing—it’s the secret ingredient that takes your sewing from “meh” to marvelous!